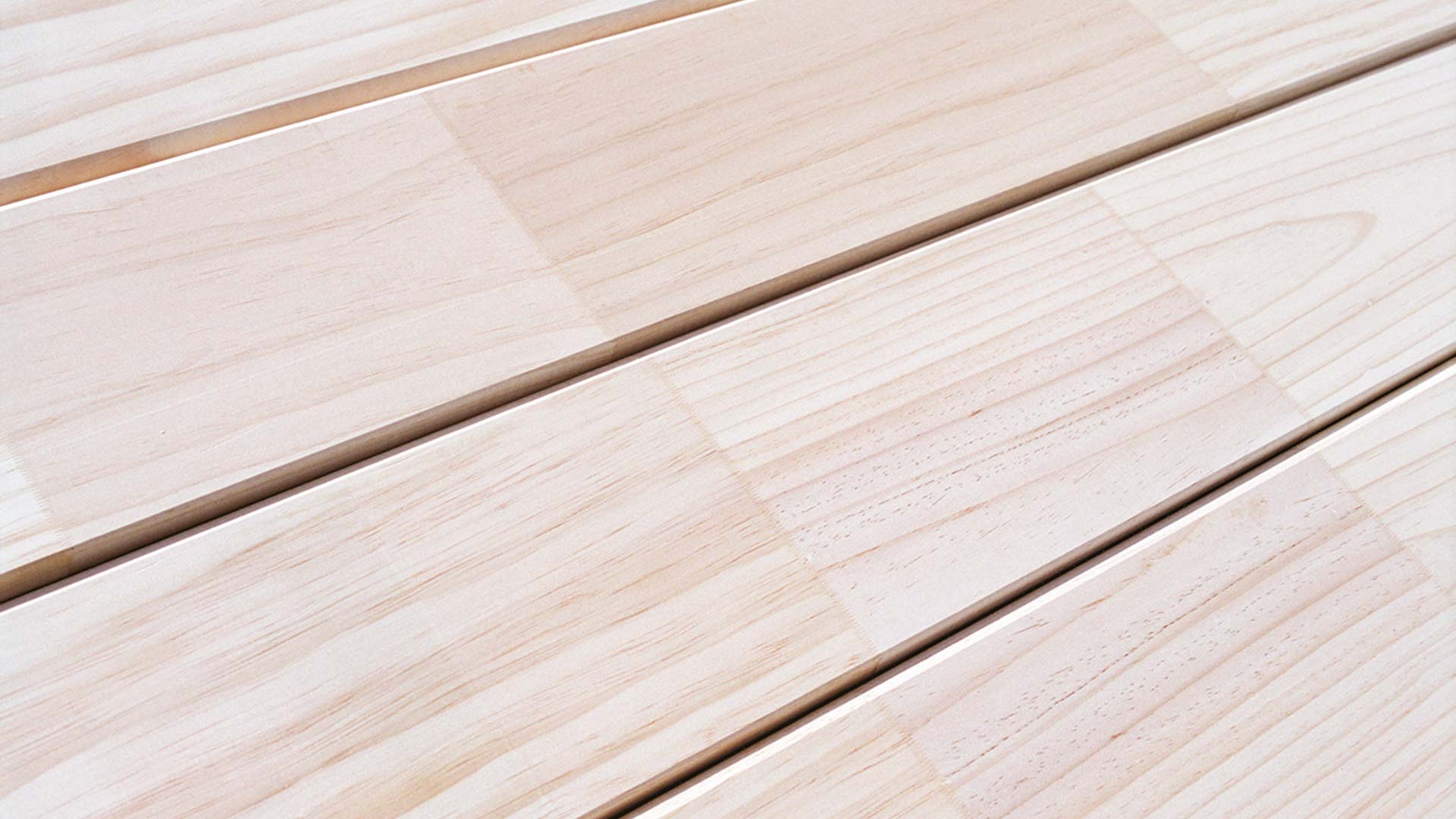

Finger Jointed Timber

Finger jointed products are created from quality New Zealand pine from which defects, such as knots, have been removed. Finger joints are precisely cut into the pieces of timber, and each joint is then glued in place. This creates a product with stability and strength superior to the original pieces of timber.

Finger jointing is used for structural products such as laminated beams, and also for appearance products, such as balustrades, fascia and weatherboards.The products created from our finger jointed timber are easy to handle. They have excellent machining qualities, and a high quality finish can be achieved.

Niagara is proud to be one of New Zealand’s leading timber processors. With over 86 years in the timber industry, and 30 years manufacturing Niagara is the trusted name in finger jointed products in New Zealand and overseas. In 2018 Niagara completed the install of a new state of the art remanufacturing plant at the Kennington Site. Designed with high multi-functionality and flexibility in mind, the finger jointing line encompasses many production processes within one single system. From start to finish, the line takes in raw material and produces two types of finished, flawless, finger jointed products (horizontal and vertical). Rough sawn kiln dried timber coming into the remanufacturing plant is machined through a Ledinek planer to give a smooth uniform finish ready for defecting and finger jointing. The timber is then scanned through a Goldeneye 500 at up to 220 metres per minute. The Goldeneye 500 Multi-Sensor Scanner precisely recognises and localises wood defects selecting only the best material for finger jointing.

This information is then communicated to four System TM Opti-Kap saws that remove all defects and knots producing a clear timber shook ready for finger jointing. Niagara produces both vertical and horizontal finger joints, giving the flexibility to offer either a face-to-face or edge-to-edge joint in lengths ranging from 1.8 to 7.2 metres.

The range of products produced is large and varied and includes door jambs, window reveals (liners), mouldings, laminated posts and beams, fascia, trim boards and edge glued wide boards. Throughout the manufacturing process there are documented quality assurance systems to guarantee customers only receive product that meets their specification. Niagara’s finger jointing operation is certified and independently audited to AS/NZS 1491 and AS 5068, which is yet another way Niagara guarantees customers’ expectations will always be met.

As well as selling finished manufactured goods, Niagara is also able to provide finger jointed blanks ready to be further manufactured. Finger jointed blanks are available for both the New Zealand domestic market and export customers. Niagara finger jointed blanks are of a visual clear grade with a moisture content of 12% + -2%.

Ex 25mm Sawn:

Blank size: 22mm x 72mm, 95mm, 120mm, 145mm and 195mm

Ex 32mm Sawn:

Blank size: 28mm x 72mm, 95mm, 120mm, 145mm and 195mm

Ex 38mm Sawn:

Blank size: 34mm x 72mm, 95mm, 120mm, 145mm and 195mm

Ex 50mm Sawn:

Blank size: 45mm x 72mm, 95mm, 120mm, 145mm and 195mm

Sawn

Thickness

25mm

32mm

38mm

50mm

FJ

Blank

22mm

28mm

34mm

45mm

Dressed

Thickness

18mm

25mm

30mm

42mm

Sawn

Width

75mm

100mm

125mm

150mm

200mm

FJ

Blank

72mm

96mm

120mm

145mm

195mm

Dressed

Width

66mm

90mm

115mm

140mm

187mm